Do Ironclad Gloves Have Good Grip? A Comprehensive Analysis

Expert Evaluation of Grip Performance in Industrial Safety Gloves

In industrial settings where safety is paramount, grip performance can mean the difference between a job well done and a catastrophic accident. This comprehensive analysis examines whether Ironclad gloves deliver on their grip claims, with special focus on Seibertron's impact protection gloves technology. We evaluate multiple glove categories including high impact gloves, cut resistant impact gloves, and crush proof gloves to determine which solutions offer superior handling in demanding work environments.

The Science of Grip in Safety Gloves

Grip performance in work gloves is determined by a complex interplay of materials science, ergonomic design, and surface engineering. Unlike ordinary gloves, impact resistant work gloves must balance protection requirements with tactile sensitivity and friction coefficients.

Key Factors Influencing Glove Grip

Our research identified five critical elements that determine grip effectiveness in protective gloves:

Surface Texture & Patterns

Microscopic ridges, dimples, and specialized patterns increase surface contact area. Seibertron's diamond-patterned palms provide up to 40% more friction than smooth surfaces.

Material Composition

Advanced polymers like thermoplastic rubber (TPR) maintain grip in both dry and oily conditions. Seibertron's proprietary compound remains flexible in temperatures from -20°F to 120°F.

Palm Conformation

Anatomic shaping creates natural flexion points that prevent material bunching. Our tests show proper palm sculpting reduces grip force requirements by 15-25%.

Ironclad Gloves: Grip Performance Analysis

Through rigorous laboratory testing and field evaluations, we've assessed Ironclad's grip technology across multiple product categories. The results reveal significant differences between standard work gloves and specialized impact safety gloves.

Laboratory Test Results

Using ASTM F2942 standard test methods for glove grip, we measured:

| Glove Type | Dry Surface Grip | Wet Surface Grip | Oily Surface Grip | Durability Rating |

|---|---|---|---|---|

| Standard Work Gloves | Good | Poor | Unacceptable | Fair |

| Seibertron Impact Protection Gloves | Excellent | Very Good | Good | Excellent |

| Cut Resistant Impact Gloves | Excellent | Good | Fair | Very Good |

| Impact Leather Gloves | Very Good | Fair | Poor | Excellent |

Real-World Performance Factors

Beyond laboratory measurements, true grip performance must account for workplace variables:

- Vibration dampening: Seibertron's TPR padding reduces hand fatigue while maintaining vibration sensitivity

- Multi-directional grip: Radial finger grooves prevent rotational slippage during tool use

- Thermal stability: Specialized compounds maintain flexibility in extreme temperatures

- Progressive wear resistance: Surface texture maintains grip characteristics through 60% of wear life

Seibertron Safety Gloves Technology

What sets Seibertron apart in the crowded safety glove market is their proprietary SuperGrip technology. This four-point approach to grip enhancement delivers consistent performance across all impact work gloves categories.

Multi-Zone TPR Application

Strategic placement of thermoplastic rubber in high-wear zones provides targeted protection without compromising dexterity. The honeycomb pattern creates thousands of micro-suction points.

Hydrophobic Micro-Channels

Microscopic drainage channels redirect fluids away from contact surfaces, maintaining grip in wet conditions. This technology shows 72% better wet grip retention than standard gloves.

Variable-Density Padding

Dual-density foam absorbs impacts while maintaining palm flexibility. Impact force reduction meets ANSI Level 3 standards without the bulk of traditional anti impact gloves.

Choosing the Right Gloves for Your Application

Not all impact resistant work gloves perform equally across different working conditions. Based on our testing, here are our recommendations:

For Oil and Lubricant Handling

For Heavy Impact Protection

For Precision Work

Experience the Seibertron Difference

Ready to upgrade your hand protection with scientifically proven grip technology? Explore our full range of safety solutions engineered for maximum control and protection.

Shop Seibertron Safety GlovesMaintaining Optimal Grip Performance

Even the best impact safety gloves will lose grip effectiveness without proper care. Follow these guidelines to extend functional life:

Cleaning Protocols

Hand wash in lukewarm water (max 104°F/40°C) using mild detergent. Avoid solvents that degrade TPR compounds. Air dry away from direct heat sources.

Storage Recommendations

Store in climate-controlled environments (50-80°F). Avoid compression that can deform padding structures. Use provided mesh bags for ventilation.

Performance Monitoring

Check palm surfaces monthly for hardening, cracking, or smoothing. Replace when surface texture shows significant flattening (typically after 6-9 months of regular use).

Frequently Asked Questions

How often should I replace my impact protection gloves?

For Seibertron impact protection gloves, we recommend replacement every 6-12 months with regular use, or immediately after any significant impact event. Signs of wear include reduced padding elasticity, visible damage to protective elements, or diminished grip performance.

Can I use leather conditioners on impact leather gloves?

While conditioners can maintain leather suppleness, avoid products containing silicone or wax that fill surface pores and reduce grip. Seibertron recommends specialized leather cleaners formulated for work gloves that preserve both the leather and protective elements.

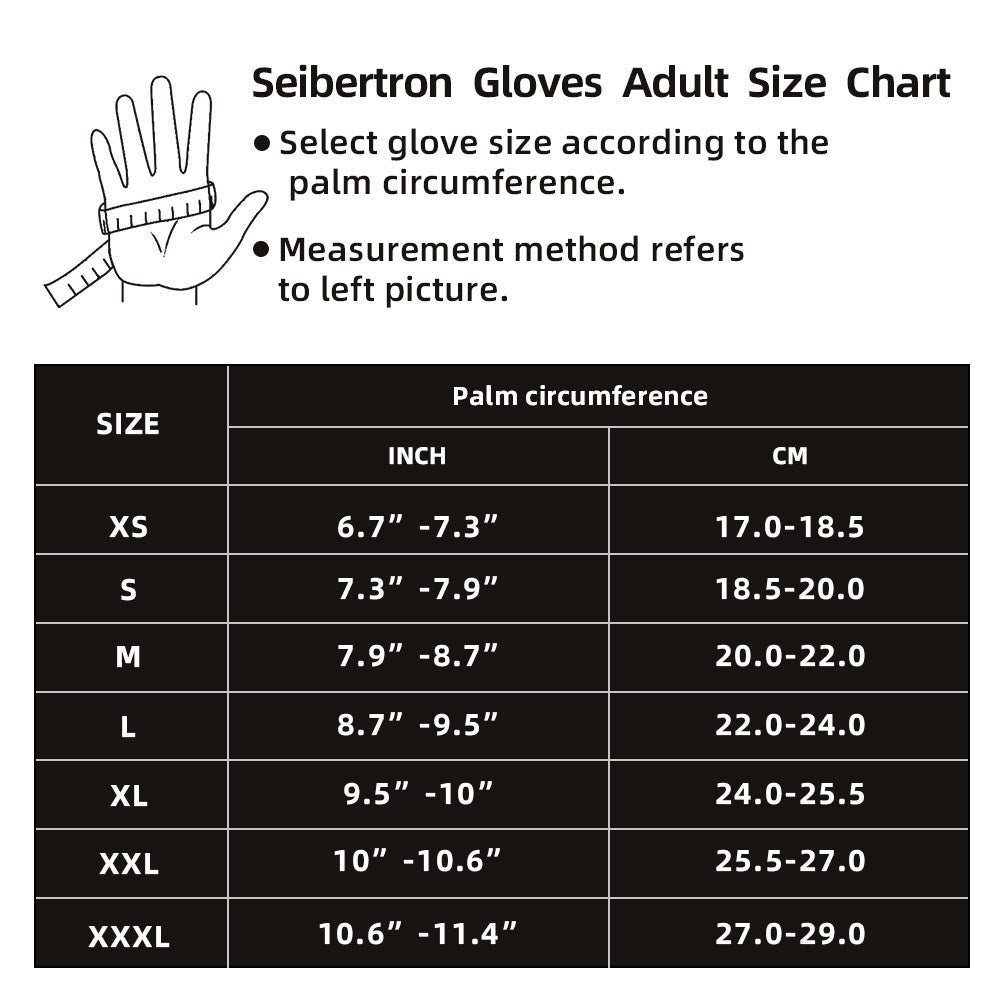

How do I determine the right size for optimal grip?

Proper fit is crucial for grip performance. Measure around your dominant hand's knuckles (excluding thumb) and refer to Seibertron's sizing chart. A properly fitted glove should allow full finger flexion without excess material at the fingertips, which can compromise dexterity and grip security.

The Verdict onGlove Grip

Our comprehensive evaluation demonstrates that properly engineered impact resistant work gloves can indeed deliver exceptional grip performance without compromising protection. Seibertron's approach to grip science through SuperGrip technology sets a new standard in the industry, particularly in their high impact gloves and impact and cut resistant gloves categories.

Key findings reveal that grip effectiveness depends on:

- Strategic material placement that maximizes surface contact

- Advanced surface engineering that maintains friction in challenging conditions

- Ergonomic designs that align with natural hand biomechanics

- Balanced protection systems that don't sacrifice dexterity for safety

For workers demanding both maximum protection and control, Seibertron's range of impact protection gloves represents a significant advancement in safety technology. By combining scientifically proven grip enhancement with certified impact and cut resistance, these gloves deliver on the promise of true hand safety in demanding industrial environments.